-

-

- Spiral welded pipe equipment

- High frequency straight seam welded pipe production line

- Hot-rolled seamless pipe equipment

- Ductile iron pipe production line

- Hot push pipe bending equipment

- Hydraulic testing machine

- Beveling machine

- Expander

- Steel pipe straightening machine

- Packaging production line

- Finishing line

-

Accessories for welding machine and medium and high frequency equipment

- Submerged arc welding - wire feeder

- Submerged arc welding - control circuit board

- Cutting machine - cutting head

- High-frequency welding - welding the large arm and small arm

- High-frequency welding - circuit boards and components

- Medium frequency annealing - induction heater

- Anti-corrosion special - medium frequency inductor

-

Hot rolling equipment accessories

- Continuous casting steelmaking spare parts

- Heat-resistant roller

- Heating unit and components

- Spindle connection unit and coupling

- Elastic damping device

- Rolling mill

- 1#, 2#, 3# flying shears

- Entrance guard device

- Other parts of the rolling mill

- Transmission components

- Copperware

- Accessories for water sports equipment

- Cooling accessories

Products -

SolutionThe equipment manufactured by the company is widely used in the processing of basic building materials, aerospace, automobile manufacturing, construction machinery manufacturing, transportation, municipal bridges and hvac, national-level oil pipeline construction, port infrastructure, marine bridge engineering, river dam and embankment construction, green energy and other industrial applications.

-

About usSichen Machinery is a global provider of automation solutions for metallurgical equipment, mainly engaged in the research, development, production, and sales of metallurgical products such as rolling mills and pipe-making equipment.

-

ServiceThe company will rely on a large number of technical research and development and on-site commissioning experience accumulated in the manufacture of various equipment in the past two decades, relying on the domestic and international markets, and is committed to providing high-quality products and services to the majority of users.

ABOUT US

Taiyuan Sichen Machinery Equipment Co., Ltd. Registered address: 22nd Floor, Zhongtai Plaza, Yingze District, Taiyuan City, Shanxi Province. It is a private high-tech enterprise integrating scientific research, manufacturing and service based on high-tech industrial technology products. The registered capital of the company is 20 million yuan.Mainly engaged in the design and manufacture of metallurgical heavy machinery and equipment, and undertake the design, development and manufacture of various types of complete production line engineering projects.

Si Chen Machinery can provide all kinds of straight seam welded pipe units, spiral welded pipe units, vertical and horizontal shear equipment, cold-formed steel equipment and other production line non-standard equipment, as well as steel plate cold rolling equipment, wire bar rolling equipment, seamless pipe rolling mill equipment, sheet and pipe finishing equipment and other heavy-duty equipment design, manufacturing, installation and commissioning, transformation, anticorrosive production equipment, galvanized equipment and spare parts technology and services.

Deepen the field of metallurgical equipment automation and continue to provide customers with favorable value

The main supporting equipment of Si Chen Machinery products adopts domestic and international advanced, mature and excellent supporting resources to ensure the high performance and high reliability of the products.A rigorous manufacturing and control management system, with lean production as the core production method, eliminates waste in the production process.Use a scientific production management system to ensure the smooth and efficient operation of the production system.

Si Chen Machinery has established a quality management system that meets the requirements of ISO9001:2000.Ensure the production and provision of Zhijin heavy machinery products that meet relevant laws, regulations and user requirements and are in line with standard requirements, and guarantee users in terms of product safety, performance, function, life, reliability and service.

Company establishment

Factory area

Countries and regions

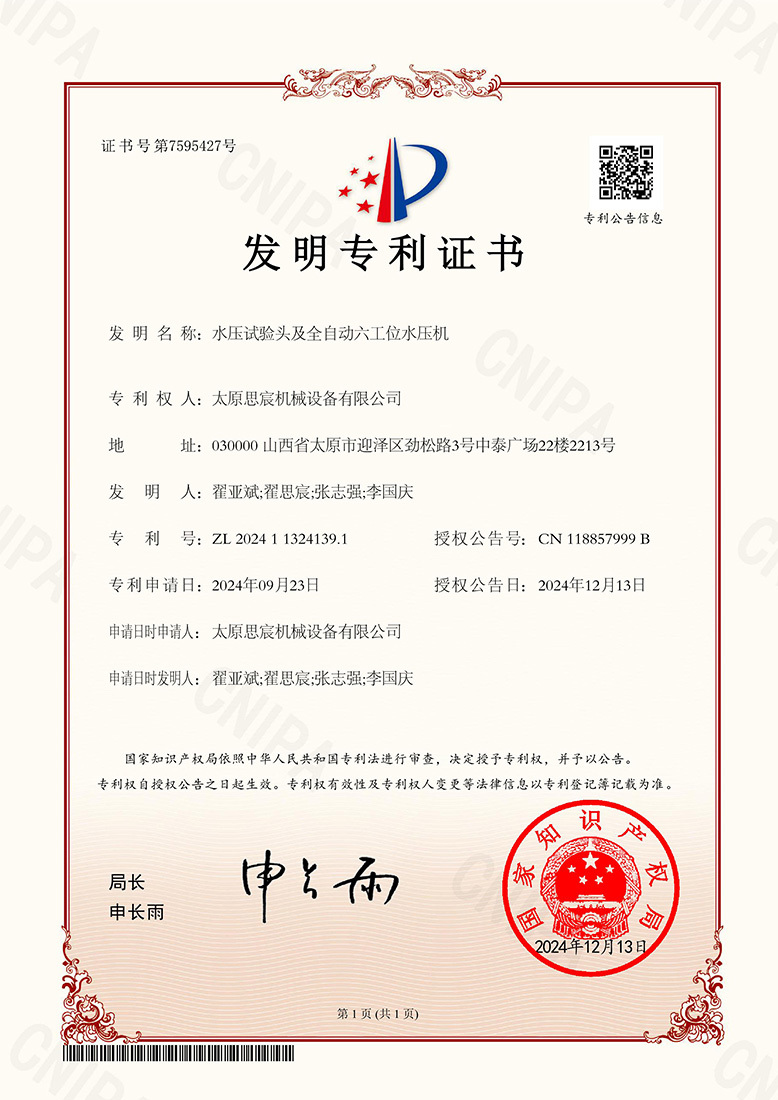

Core patents

Si Chen Machinery has learned from the service concepts of advanced enterprises at home and abroad, combined with the actual situation of the company, and in line with the service tenet of “fast, accurate, thoughtful and cordial”, it has established a perfect service guarantee system in the pre-sale, sale and after-sale, to provide users with strong technical services and product support in all regions, all hours and borderless at any time.

Si Chen Machinery brings together a group of 5 core technical backbone and 7 technical designers with more than 15 years of product research and development experience in the metallurgical machinery industry, and 34 production departments. It has 2 CNC machining centers, 6 CNC lathes, 3 CNC gantry milling machines, and 2 boring machines. It has mature technology and management experience in product research and development, manufacturing, and operation and management, so that the company's operations can quickly enter the right track and high-speed development track.

A better future is based on today's unremitting efforts.Companies adhering to the core concept of ”people-oriented, integrity, scientific and technological development", are committed to building a high-quality, high-tech and high-service equipment manufacturing enterprise.

The welded pipe equipment business is one of the company's core businesses that entered the field of Zhijin heavy machinery and equipment in the early days. The products include straight seam welded pipe units, spiral welded pipe units, special material welded pipe units, a full range of production line equipment and steel pipe finishing and deep processing equipment.

Culture

Installation and Commissioning

The smooth operation of mechanical equipment is key to ensuring that customers can leverage their competitive advantages and achieve business value. Sichen Machinery's installation and commissioning services cover all necessary items, including the installation of equipment manufacturing machinery, hydraulic and electrical systems, and related performance testing.

Production Support

Sichen Machinery's experts will provide on-site production start-up support for customers, promptly identifying and resolving any equipment malfunctions that could lead to high costs, ensuring customers achieve stable production processes.

Spare Parts Support

Every spare part produced by Sichen Machinery is carefully manufactured for the corresponding equipment, which is also an important reason why the equipment can retain its value for a long time. We will deliver them quickly to the user's site to ensure production.

Upgrades and Retrofits

Sichen Machinery's innovative spirit gives its products enormous potential for upgrades. Even mechanical equipment that has been in operation for many years can be rejuvenated through upgrades and modifications.

Maintenance and Optimization

Sichen Machinery's service experts can provide customized equipment maintenance plans for customers based on their different needs. Maintenance services include personalized maintenance services and comprehensive maintenance recommendations.

Equipment Inspection

Through the application of modern equipment and measurement methods, Sichen Machinery's experts continuously explore the improvement potential of customer equipment, and regular equipment inspections will effectively prevent unexpected equipment failures.

Qualifications

History

2012

2013

2015

2016

2017

2018

2019

2020

2021

2023

24-hour mobile phone:

Service Hotline

Service Email

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.