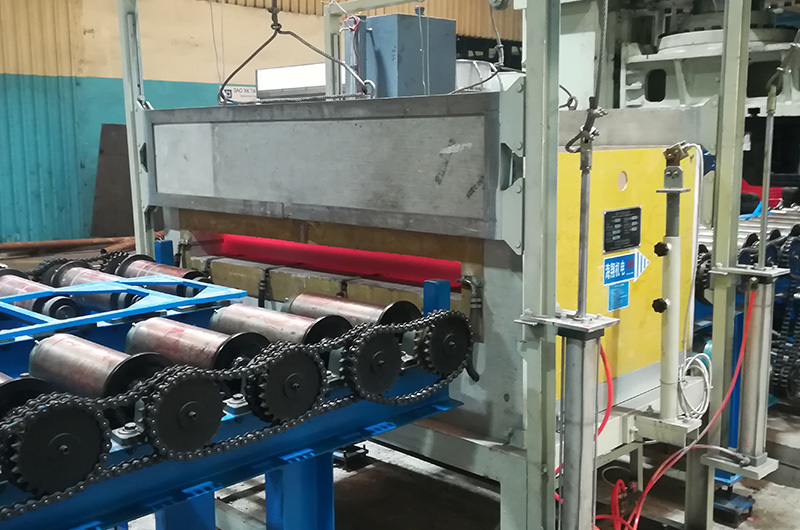

Hot extrusion production line

The hot press production line is a large-scale press production line independently researched, manufactured, and tested by Si Chen Machinery to meet the needs of automobile engine casting factories, converting castings into forgings.