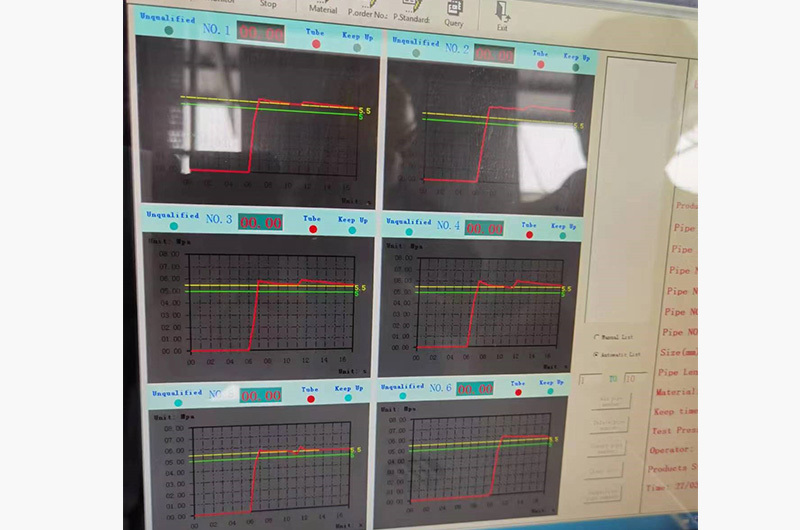

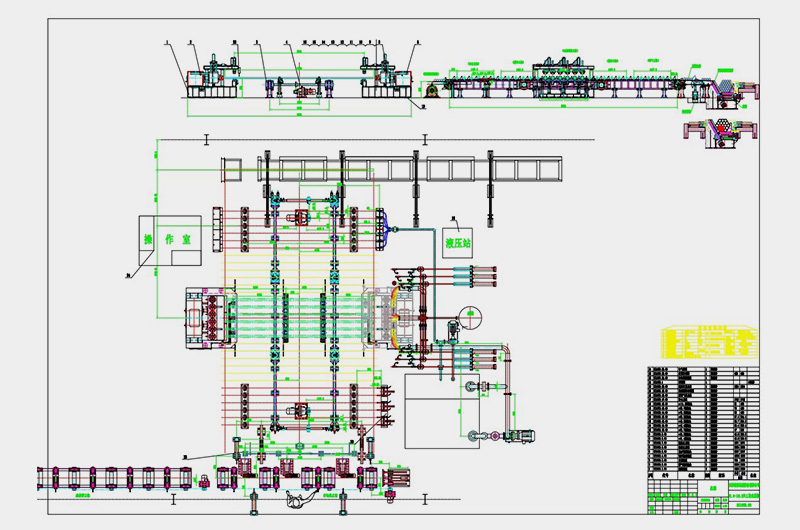

The number of test stations has been increased, improving detection efficiency. Each steel pipe can be tested independently, outputting an independent test pressure curve. Substandard pipes are automatically spray-coded and identified. It has the advantages of non-destructive testing of steel pipes, fast rhythm, etc. The operation process is controlled by PLC, with a human-machine interface, original data storage, system parameter setting, independent pressure curve display, operating status display, counting, and printing functions, making it efficient, stable, and easy to maintain.

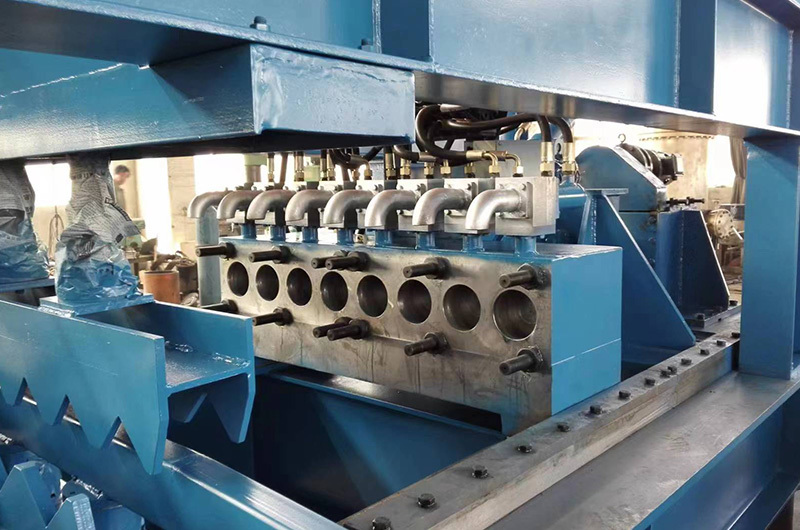

Each steel pipe can be tested independently; it is not necessary to gather steel pipes from all stations before testing; independent station structure design and loop system design.