-

-

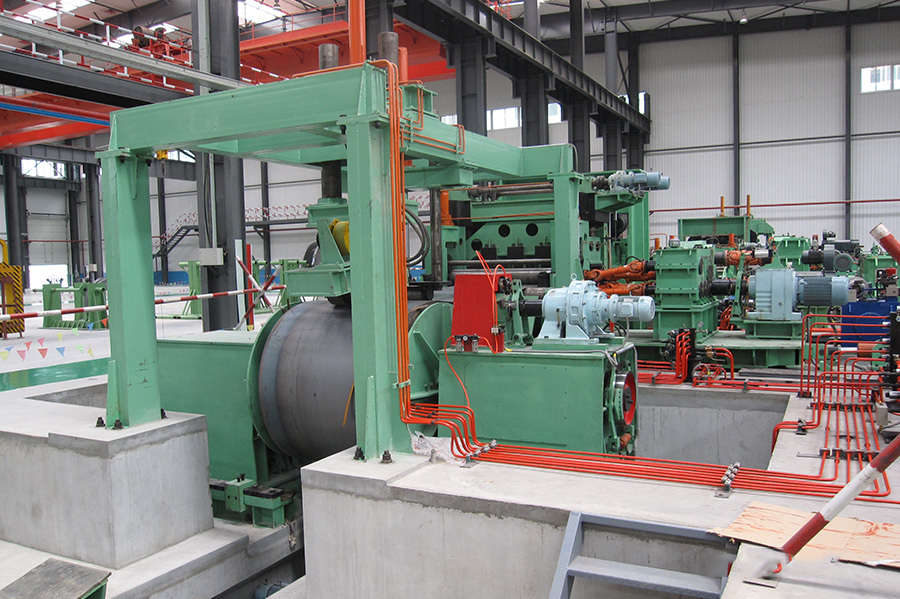

- Spiral welded pipe equipment

- High frequency straight seam welded pipe production line

- Hot-rolled seamless pipe equipment

- Ductile iron pipe production line

- Hot push pipe bending equipment

- Hydraulic testing machine

- Beveling machine

- Expander

- Steel pipe straightening machine

- Packaging production line

- Finishing line

-

Accessories for welding machine and medium and high frequency equipment

- Submerged arc welding - wire feeder

- Submerged arc welding - control circuit board

- Cutting machine - cutting head

- High-frequency welding - welding the large arm and small arm

- High-frequency welding - circuit boards and components

- Medium frequency annealing - induction heater

- Anti-corrosion special - medium frequency inductor

-

Hot rolling equipment accessories

- Continuous casting steelmaking spare parts

- Heat-resistant roller

- Heating unit and components

- Spindle connection unit and coupling

- Elastic damping device

- Rolling mill

- 1#, 2#, 3# flying shears

- Entrance guard device

- Other parts of the rolling mill

- Transmission components

- Copperware

- Accessories for water sports equipment

- Cooling accessories

Products -

SolutionThe equipment manufactured by the company is widely used in the processing of basic building materials, aerospace, automobile manufacturing, construction machinery manufacturing, transportation, municipal bridges and hvac, national-level oil pipeline construction, port infrastructure, marine bridge engineering, river dam and embankment construction, green energy and other industrial applications.

-

About usSichen Machinery is a global provider of automation solutions for metallurgical equipment, mainly engaged in the research, development, production, and sales of metallurgical products such as rolling mills and pipe-making equipment.

-

ServiceThe company will rely on a large number of technical research and development and on-site commissioning experience accumulated in the manufacture of various equipment in the past two decades, relying on the domestic and international markets, and is committed to providing high-quality products and services to the majority of users.

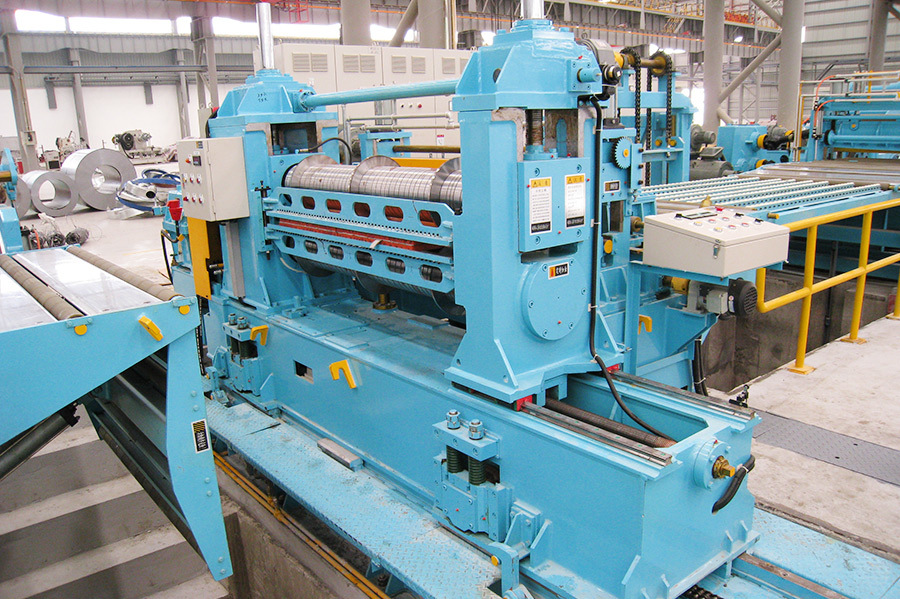

Medium plate slitting equipment

Thick plate longitudinal shearing equipment

Thick-walled horizontal shear production line

Medium plate shearing production line

Slitting and shearing line for thin plates

24-hour mobile phone:

Service Hotline

Service Email

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.