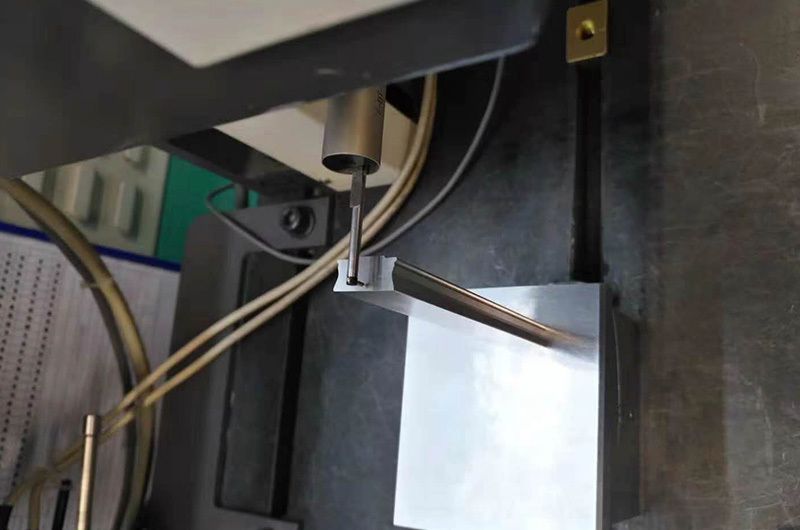

All actions are controlled by PLC. After debugging, only the workpiece needs to be placed, and the equipment processing can be completed with one button. It also performs intelligent cutting, and automatically performs conformal cutting for complex end faces. It uses a high-precision infrared instrument configured in the equipment for tool setting, making the tool setting process simple and accurate.

The equipment appearance adopts a unique structural form, which is advanced and reliable.

Product structure innovation:

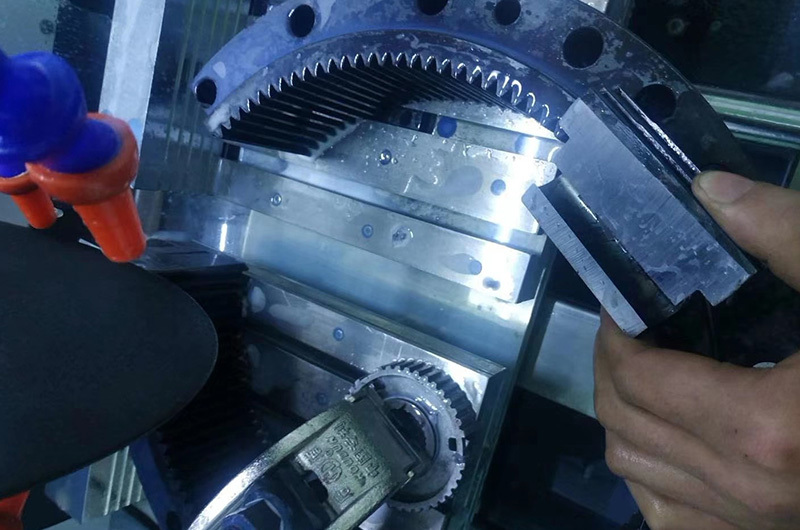

1. Add a rotary manual clamping device to improve the maximum cutting capacity of the same type of cutting machine;

2. The equipment has different cutting mode settings to meet the cutting and grinding of various products;

3. The cutting accuracy has reached the accuracy requirements of laboratory metallographic testing;

4. The cutting efficiency is 7-10 times that of wire cutting. Experiments show that when cutting large workpieces, it is about 3 times that of ordinary cutting machines.