-

-

- Spiral welded pipe equipment

- High frequency straight seam welded pipe production line

- Hot-rolled seamless pipe equipment

- Ductile iron pipe production line

- Hot push pipe bending equipment

- Hydraulic testing machine

- Beveling machine

- Expander

- Steel pipe straightening machine

- Packaging production line

- Finishing line

-

Accessories for welding machine and medium and high frequency equipment

- Submerged arc welding - wire feeder

- Submerged arc welding - control circuit board

- Cutting machine - cutting head

- High-frequency welding - welding the large arm and small arm

- High-frequency welding - circuit boards and components

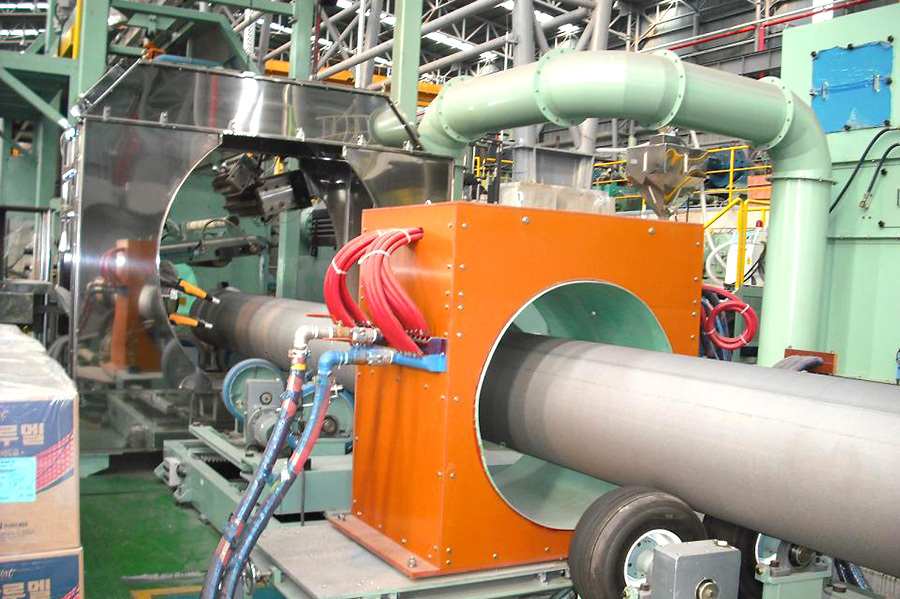

- Medium frequency annealing - induction heater

- Anti-corrosion special - medium frequency inductor

-

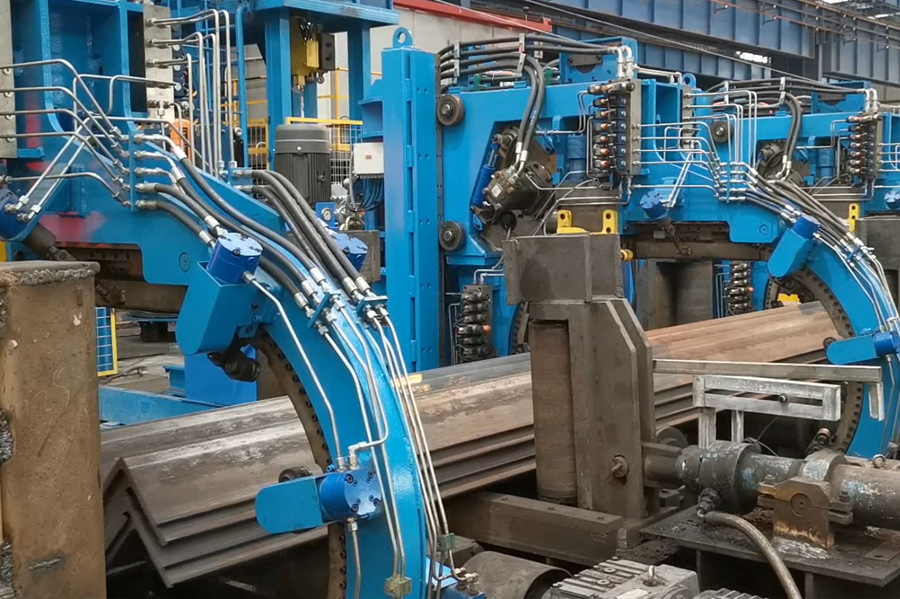

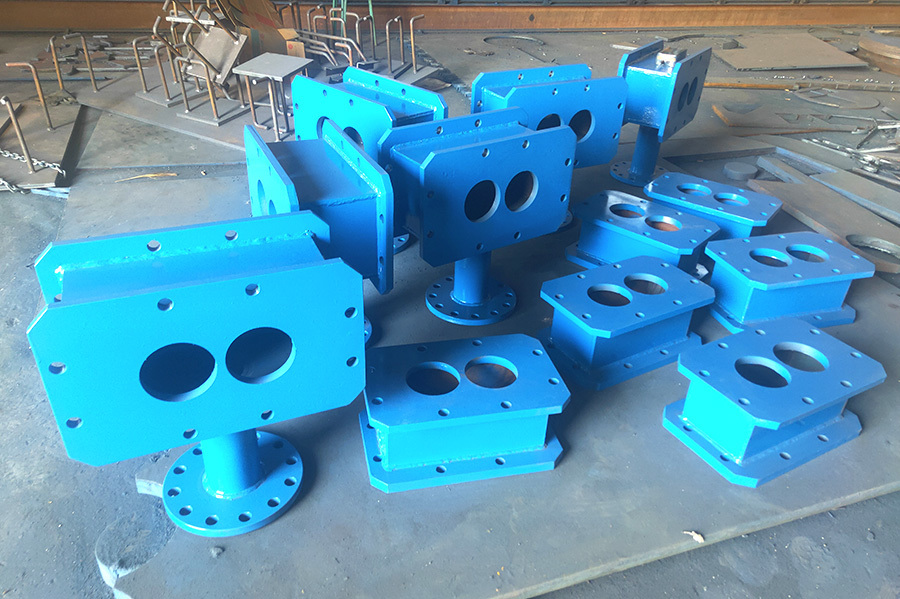

Hot rolling equipment accessories

- Continuous casting steelmaking spare parts

- Heat-resistant roller

- Heating unit and components

- Spindle connection unit and coupling

- Elastic damping device

- Rolling mill

- 1#, 2#, 3# flying shears

- Entrance guard device

- Other parts of the rolling mill

- Transmission components

- Copperware

- Accessories for water sports equipment

- Cooling accessories

Products -

SolutionThe equipment manufactured by the company is widely used in the processing of basic building materials, aerospace, automobile manufacturing, construction machinery manufacturing, transportation, municipal bridges and hvac, national-level oil pipeline construction, port infrastructure, marine bridge engineering, river dam and embankment construction, green energy and other industrial applications.

-

About usSichen Machinery is a global provider of automation solutions for metallurgical equipment, mainly engaged in the research, development, production, and sales of metallurgical products such as rolling mills and pipe-making equipment.

-

ServiceThe company will rely on a large number of technical research and development and on-site commissioning experience accumulated in the manufacture of various equipment in the past two decades, relying on the domestic and international markets, and is committed to providing high-quality products and services to the majority of users.

Share

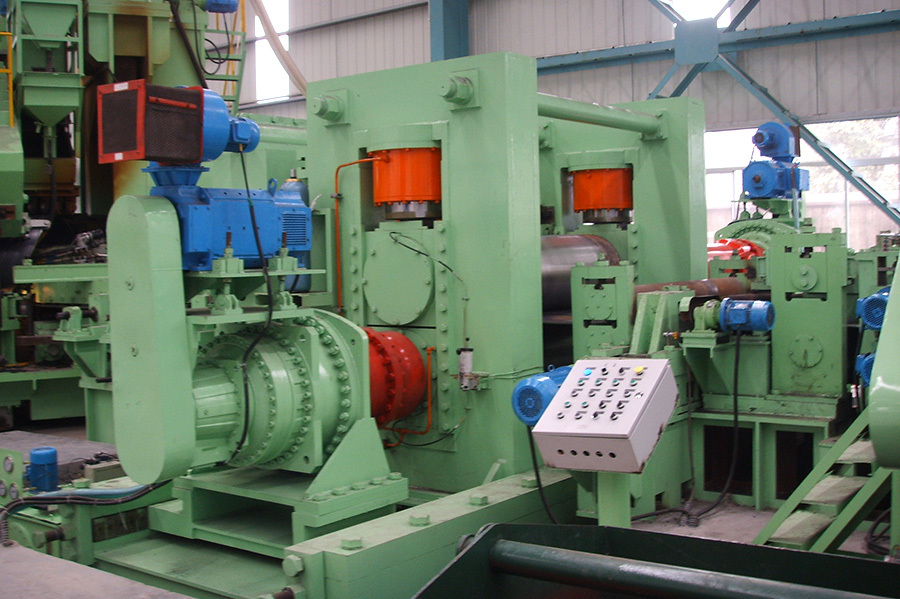

Rear-swing spiral welded pipe equipment

Still deciding? If you are interested, you need to take a sample first, Contact us!

Product Category

Spiral welded pipe equipment

Tags

Metallurgical heavy machinery and equipment

- Product description

- Homepage Product - Related Calls

-

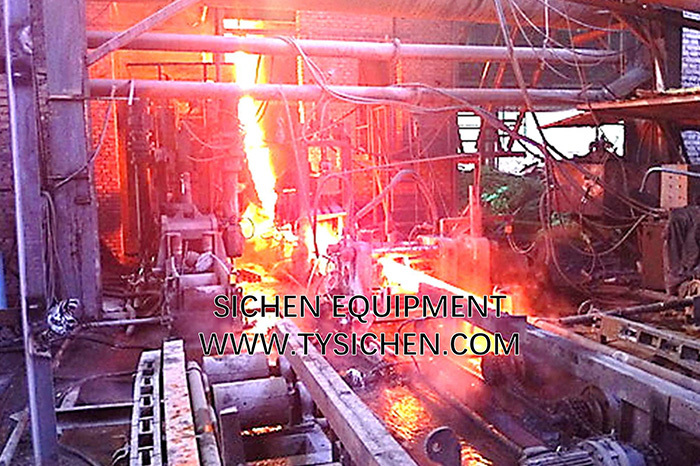

The reversing type is one of the unit forms of spiral welded pipe equipment. Through the adjustment of the rear bridge, which can rotate around the forming rotating point, its process preparation equipment is installed on the flying welding carriage, which can realize continuous uninterrupted production.

Product Introduction

The reversing type is one of the unit forms of spiral welded pipe equipment. Through the adjustment of the rear bridge, which can rotate around the forming rotating point, its process preparation equipment is installed on the flying welding carriage, which can realize continuous uninterrupted production. It is often used in pipeline production in the fields of petroleum, natural gas, water transportation, and building structures. This type of equipment produces high-strength and pressure-resistant spiral welded pipes by rolling steel strips into a spiral shape and welding at the seams.

Main Features

• High production efficiency: Continuous production, this equipment usually has a high degree of automation and high production efficiency, suitable for mass production.

• Wide applicability: Suitable for producing spiral welded pipes of different diameters and thicknesses, with greater adaptability.

Process Flow

Coil preparation—Uncoiling—Straightening—Clamping and feeding—Leveling—Butt welding/Cutting butt welding—Flying welding carriage—Live loop—Clamping and feeding—Circular shear/Edger—Delivery—Pre-bending—Guide plate—Forming—Internal welding—External welding—Sizing cutting—Pipe dropping to pipe conveying trolley—Finished product collection

Specifications and Models

Model

Minimum Diameter

Maximum Diameter

Minimum Wall Thickness

Maximum Wall Thickness

Applicable Plate Width

Maximum Production Capacity

Floor Space

Mm

mm

mm

mm

mm

Ton/year

㎡

SCLH-400

219-325

325-426

2-4

4-8

350-500

6000-10000

18x96

SCLH-600

219-508

426-630

2-4

4-10

400-600

7000-11000

20x98

SCLH-800

219-508

325-820

2-4

4-10

400-600

8000-12000

24x145

SCLH-1000

219-508

406-1020

2-4

4-12

400-750

9000-17000

24x145

SCLH-1200

219-508

406-1220

2-4

4-12

400-1050

10000-18000

24x156

SCLH-1400

219-508

406-1420

2-4

4-14

400-1050

13000-20000

24x156

SCLH-1600

219-508

630-1620

2-4

4-14

500-1250

16000-23000

24x158

SCLH-1800

406-610

630-1820

3-6

8-18

500-1500

26000-35000

30x158

SCLH-2000

406-610

720-2020

3-6

12-25.4

700~1800

28000-40000

36x158

SCLH-3000

406-610

1420-3200+

3-6

18-25.4

700~2000

36000-76000

36x175

SCLH-4000

406-610

2020-3200+

4-6

20-25.4

1000~2000

77000-93000

36x230

Rear-swing spiral welded pipe equipment

Still deciding? If you are interested, you need to take a sample first, Contact us!

Product Category

Tags

Metallurgical heavy machinery and equipment

Get a Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.

Related Products

24-hour mobile phone:

Service Hotline

Service Email

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.