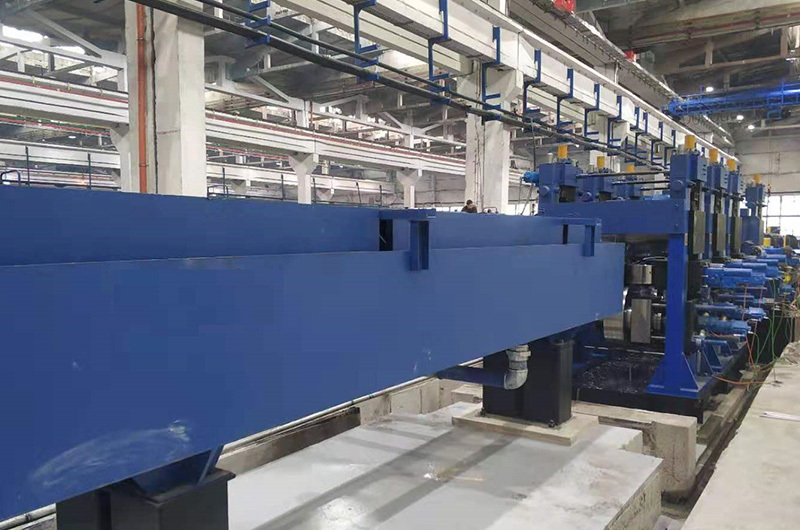

Automatic Square and Rectangular Tube Forming Production Line

Automatic forming square and rectangular tube mill, adopts electric adjustment to directly form square and rectangular tubes. When changing product specifications, only the relevant parameters such as pipe diameter and wall thickness need to be input, and then the roller position will be automatically moved, with one-button adjustment.