-

-

- Spiral welded pipe equipment

- High frequency straight seam welded pipe production line

- Hot-rolled seamless pipe equipment

- Ductile iron pipe production line

- Hot push pipe bending equipment

- Hydraulic testing machine

- Beveling machine

- Expander

- Steel pipe straightening machine

- Packaging production line

- Finishing line

-

Accessories for welding machine and medium and high frequency equipment

- Submerged arc welding - wire feeder

- Submerged arc welding - control circuit board

- Cutting machine - cutting head

- High-frequency welding - welding the large arm and small arm

- High-frequency welding - circuit boards and components

- Medium frequency annealing - induction heater

- Anti-corrosion special - medium frequency inductor

-

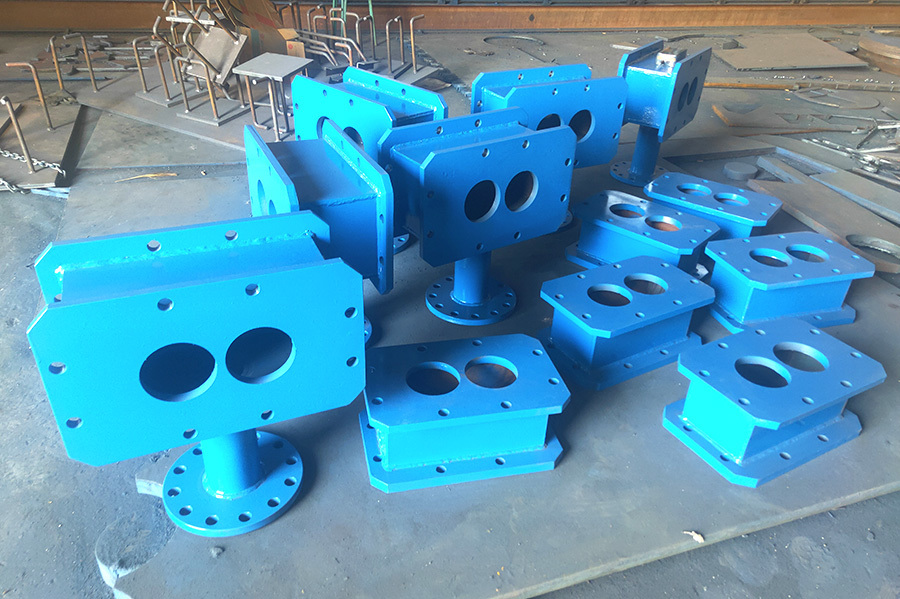

Hot rolling equipment accessories

- Continuous casting steelmaking spare parts

- Heat-resistant roller

- Heating unit and components

- Spindle connection unit and coupling

- Elastic damping device

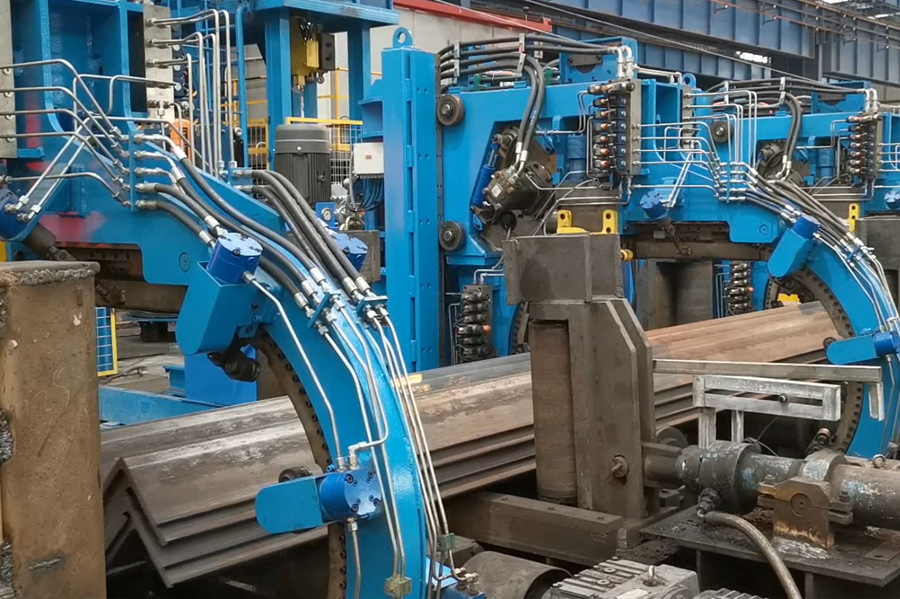

- Rolling mill

- 1#, 2#, 3# flying shears

- Entrance guard device

- Other parts of the rolling mill

- Transmission components

- Copperware

- Accessories for water sports equipment

- Cooling accessories

Products -

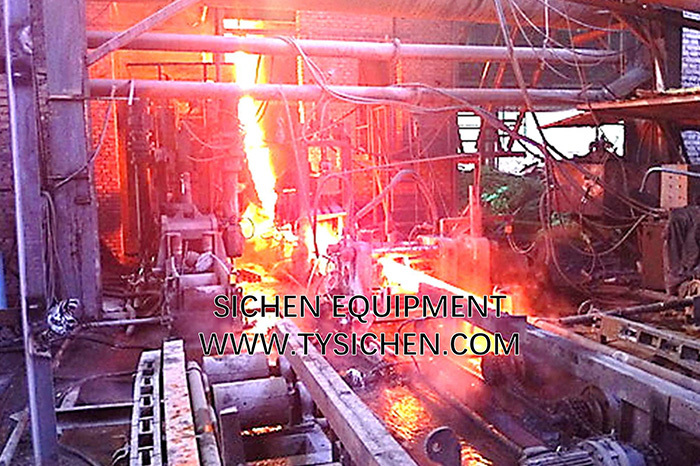

SolutionThe equipment manufactured by the company is widely used in the processing of basic building materials, aerospace, automobile manufacturing, construction machinery manufacturing, transportation, municipal bridges and hvac, national-level oil pipeline construction, port infrastructure, marine bridge engineering, river dam and embankment construction, green energy and other industrial applications.

-

About usSichen Machinery is a global provider of automation solutions for metallurgical equipment, mainly engaged in the research, development, production, and sales of metallurgical products such as rolling mills and pipe-making equipment.

-

ServiceThe company will rely on a large number of technical research and development and on-site commissioning experience accumulated in the manufacture of various equipment in the past two decades, relying on the domestic and international markets, and is committed to providing high-quality products and services to the majority of users.

Share

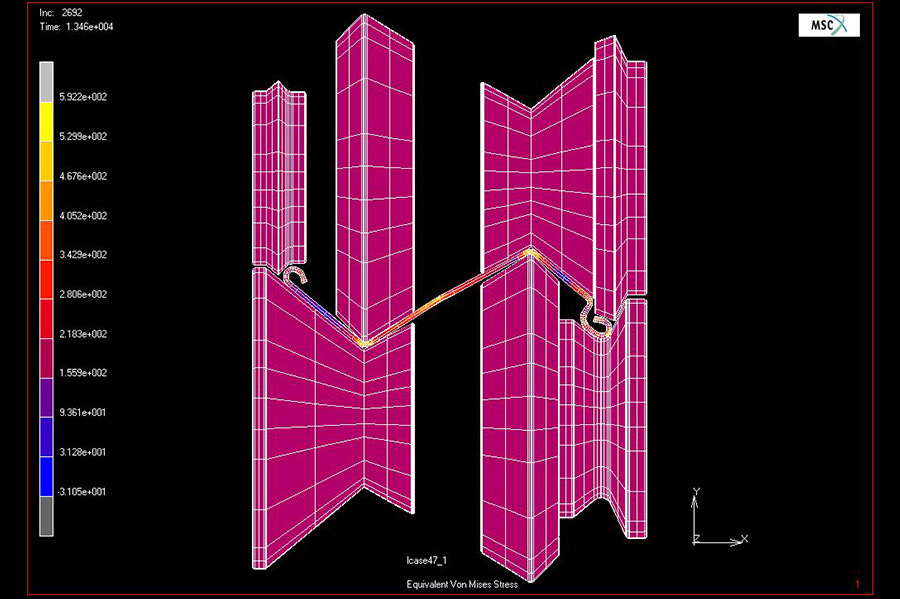

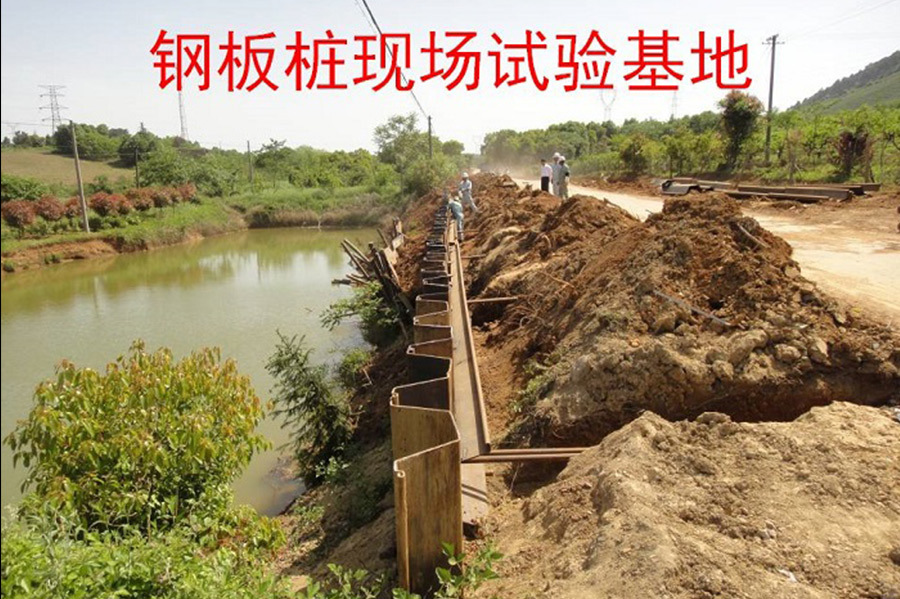

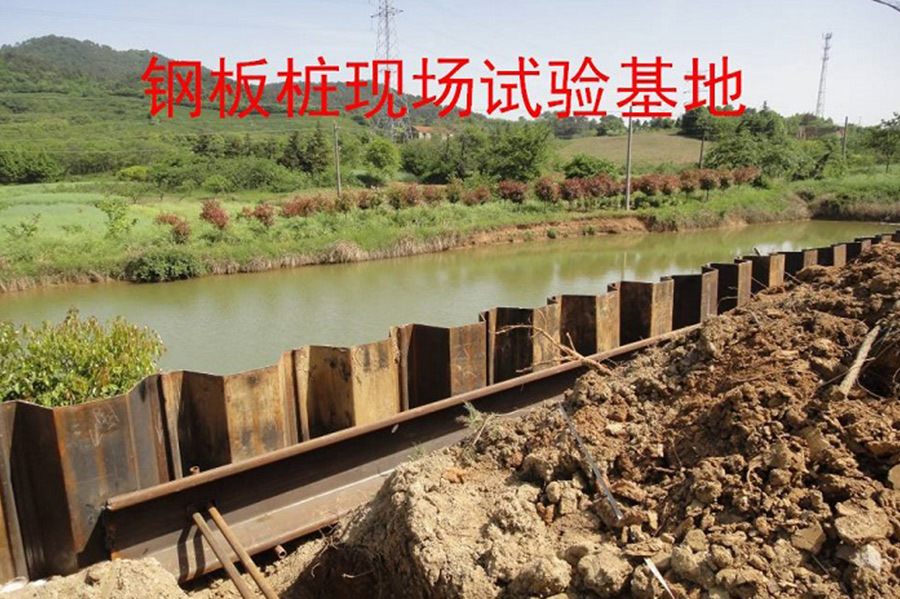

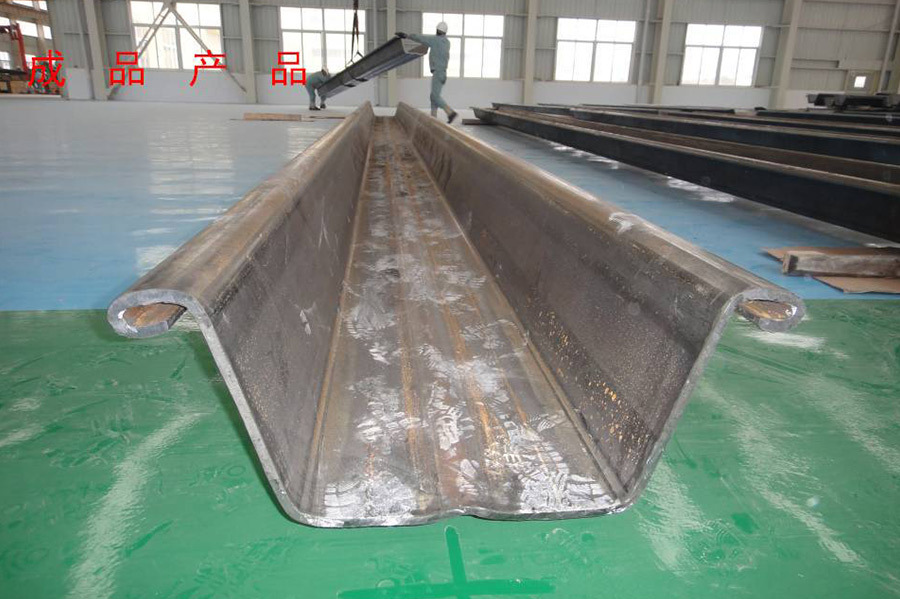

Sheet pile test development

Still deciding? If you are interested, you need to take a sample first, Contact us!

Product Category

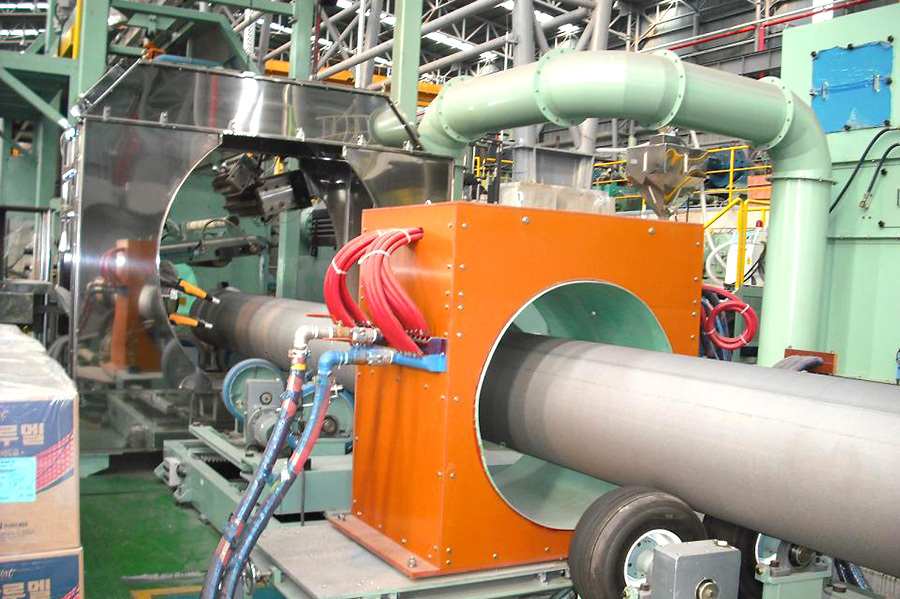

Steel sheet pile production line

Tags

Metallurgical heavy machinery and equipment

- Product description

- Homepage Product - Related Calls

-

Equipment Introduction

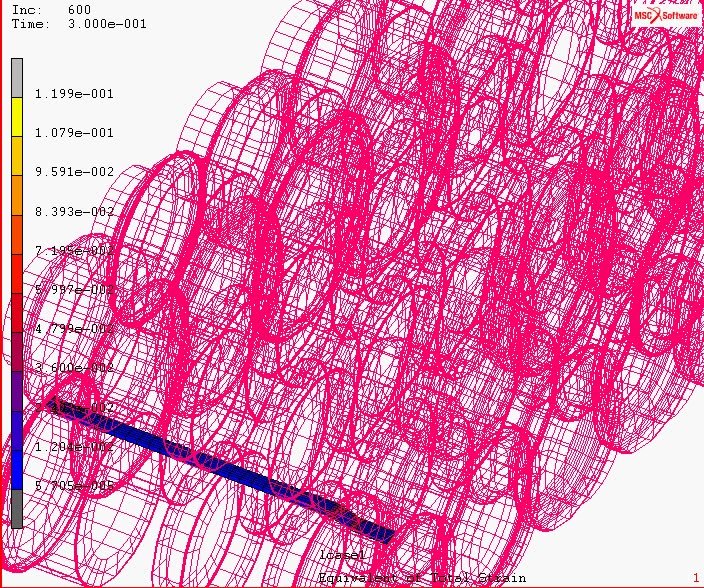

Cold roll forming lines uncoil and flatten coils of a certain width before feeding them into a forming machine, where rollers bend the steel sheet into the desired shape in a cold state.

Cold roll forming lines are roughly divided into square tube lines, sheet piling lines, and other lines, depending on the product. Square tube lines mainly produce rectangular and square tubes using direct squaring. The process is equipped with a high-frequency welder, enabling the production of all sizes of rectangular and square tubes within a specified range using a single set of rollers.

Sheet piling lines are specialized for producing sheet piles, employing a segmented arc flexible forming technology. Our company's sheet piling lines have reached a world-class level. Other models can produce various sections, such as channels and C-sections, by changing the rollers.

Process Flow

Coil feed → Decoiling → Leveling → Shearing and Butt Welding → Live Coil Storage → Forming → (High-frequency Welding) → (Intermediate Frequency Annealing) → Water Cooling → Sizing → Cutting → Output → Finished Product Collection

Selection Range

Serial Number

Type

Width (mm)

Thickness

(mm)

Applicable Coil Weight (tons)

Forming Speed (m/min)

Installed Capacity (kW)

Machine Footprint (m)

1

SCLW-1250

450~1250

3.0~14.0

30

10~25

2600

18×160

2

SCLW-1400

600~1400

4.0~14.0

30

8~20

3200

21×210

3

SCLW-1600

800~1600

4.0~16.0

30

8~20

3600

21×240

4

SCLW-2000

1000~2000

5~20.0

40

8~20

3900

21×260

Sheet pile test development

Still deciding? If you are interested, you need to take a sample first, Contact us!

Product Category

Tags

Metallurgical heavy machinery and equipment

Get a Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.

Related Products

24-hour mobile phone:

Service Hotline

Service Email

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.